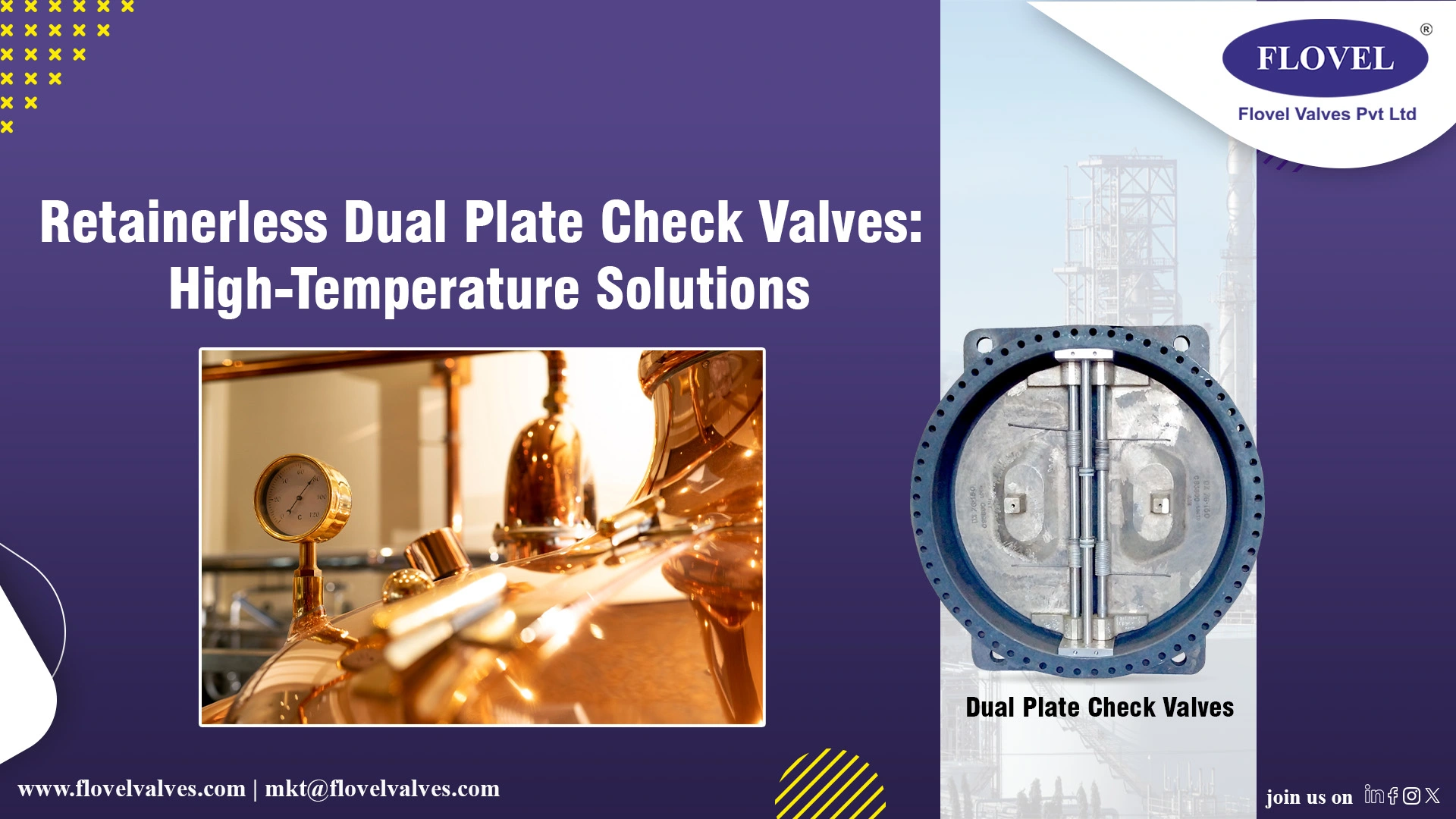

Retainerless Dual Plate Check Valve | High-Temp Solutions

At Flovel Valves Pvt Ltd., we know how demanding the gas and petrochemical industries can be. High pressure, extreme temperatures, and corrosive fluids are part of daily operations. Our Retainerless Dual Plate Check Valves are designed to handle these conditions with ease.

Withstand the Heat

In high-temperature applications, traditional check valves often leak due to pins or external bolts. These weak points can fail under heat stress. Our retainerless design removes these leak paths. This ensures tight sealing and zero emissions, even under extreme conditions. We use high-grade materials that resist heat and corrosion, making the valves reliable and long-lasting.

Easy to Maintain

Downtime hurts productivity. That’s why we designed our valves for fast and easy maintenance. The compact and lightweight body makes handling simple. With no external bolting and fewer parts, disassembly is quick. This saves time, lowers labor costs, and keeps your plant running.

Built to Global Standards

Our valves meet API 594, ASME B16.34, and other international standards. We hold API, ISO, CE-PED, and TRCU certifications. Trusted by companies like Qatar Gas, PDO Oman, and ADNOC, Flovel valves perform in critical applications around the world.

Whether you’re managing a refinery, LNG terminal, or offshore platform, our Retainerless Dual Plate Check Valves deliver the strength, safety, and simplicity your operations need.

Designed with Engineering Precision

Every Flovel Retainerless Dual Plate Check Valve is the result of careful engineering and field experience. The dual plate design uses a torsion spring to close quickly and smoothly. This avoids water hammer and protects pumps, compressors, and pipelines.

The wafer-type construction makes installation easier, especially in systems with space constraints. The lightweight nature reduces load on piping, flanges, and supporting structures, offering cost savings in both installation and long-term use.

We also offer customized trim materials, coatings, and configurations to suit your media, pressure class, and temperature rating—ensuring the valve fits your process perfectly.