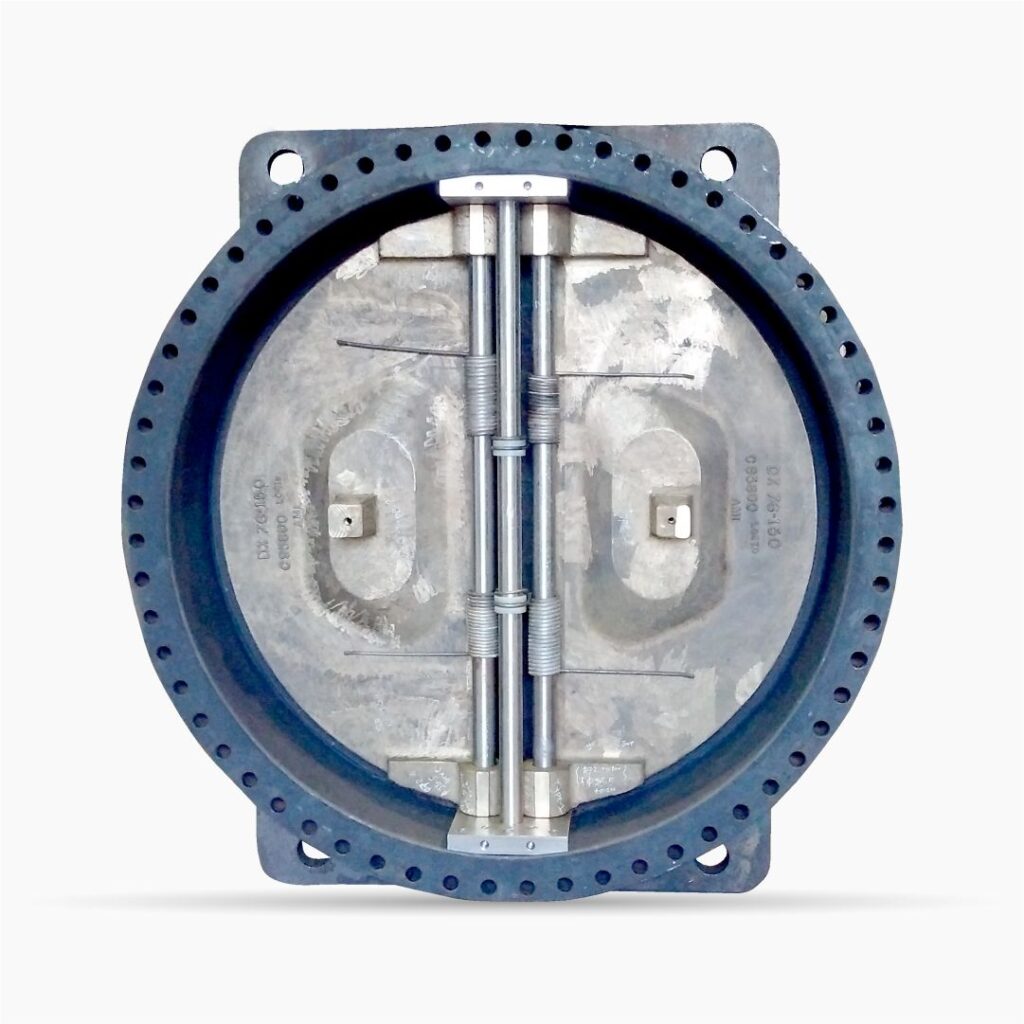

DUAL PLATE CHECK VALVE

Known for its quality and reliability at internationally competitive prices, Flovel Valves Pvt Ltd has been the market leader in designing and manufacturing Dual Plate Check Valves spanning over a period of over 3 decades supplying to Hydrocarbon, Energy and Process industries.

Owing to its exceptional network of agents and distributors, Flovel Valves has been able to build for itself a wide geographical market catering to demands of its customers in over 35 countries around the world. With a reputation of providing quality services to its customers, Flovel Valves has an extraordinary portfolio of clients from around the world including many of the world’s leading end users of oil and international engineering contractors.

The key features of these check valves and their specialization areas are as under:

- Fire Safe Design Valves

- Type Test – Validated Design

- ETT – Elevated Temperature Tested Valves

- FE – Fugitive Emission Tested Valves

- Flow Test – CV Value and Pressure Drop

- Life Cycle Tested

- CRA – Corrosion Resistance Alloy Cladded Valves (Inconel 625, Inconel 825, SS316)

- Cryogenic Application

- Hydrogen Application

- Vacuum Application

- Rubber Lined