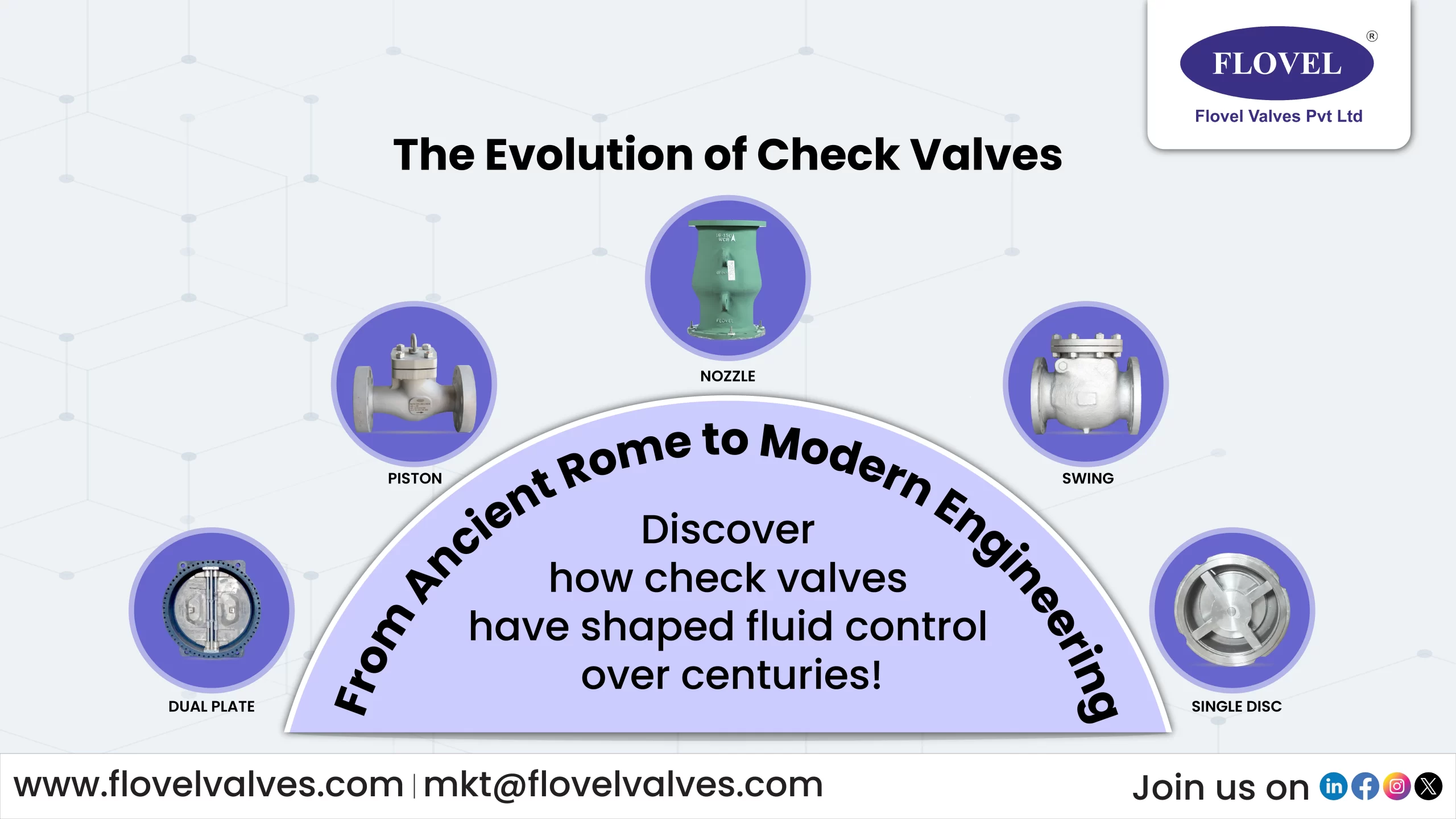

The Evolution of Check Valves: From Ancient Rome to Modern Engineering

Check valves are an essential component in fluid systems, ensuring that flow moves in the desired direction while preventing backflow that could disrupt operations or damage equipment. While today’s check valves feature advanced designs and materials, their roots can be traced back thousands of years. This blog explores the fascinating evolution of check valves, highlighting key milestones in their journey from ancient engineering marvels to modern industrial necessities.

Ancient Beginnings: The Birth of Flow Control

The concept of controlling the flow of fluids dates back to ancient civilizations. The Romans, known for their engineering prowess, used rudimentary check valves in their aqueduct systems to maintain consistent water flow and prevent contamination. These early devices were often made of wood, stone, or leather and relied on simple mechanisms like flaps or plugs to regulate water movement.

The Industrial Revolution: Pioneering Valve Innovations

The Industrial Revolution marked a turning point in the development of check valves. With the rise of steam engines and industrial machinery, the demand for reliable flow control mechanisms surged. Check valves made from metals such as iron and brass replaced earlier materials, offering greater durability and pressure-handling capabilities.

One significant advancement during this period was the introduction of the swing check valve, which used a hinged disc to allow forward flow and block reverse flow. This design quickly became a standard in industries like water distribution and steam power.

The 20th Century: Specialized Designs and Materials

As industries grew more specialized in the 20th century, so did the designs of check valves. Manufacturers began tailoring valves to specific applications, resulting in the development of:

- Dual Plate Check Valves: Featuring two spring-loaded plates, these valves offered lower pressure drops and greater efficiency in high-flow systems.

- Non-Slam Nozzle Check Valves: Designed to mitigate water hammer, these valves used spring-assisted closure mechanisms to provide smooth, noise-free operation.

- Piston Lift Check Valves: Ideal for high-pressure systems, these valves utilized a piston mechanism for precise flow control.

Advances in materials science also played a crucial role. Stainless steel, duplex alloys, and corrosion-resistant coatings allowed check valves to operate reliably in harsh environments, such as offshore oil rigs and chemical processing plants.

The Modern Era: Precision and Intelligence

Today, check valves are engineered with unparalleled precision, leveraging cutting-edge technologies such as computational fluid dynamics (CFD) and 3D modeling to optimize performance. Key trends shaping the industry include:

- Smart Valves: Integration with IoT sensors enables real-time monitoring of valve performance, ensuring predictive maintenance and reducing downtime.

- Energy Efficiency: Modern designs minimize pressure losses, contributing to energy savings in large-scale operations.

- Compliance and Certifications: Stringent standards like API6D, API594, and CE-PED ensure that valves meet global safety and performance benchmarks.

Flovel Valves: A Legacy of Excellence

Flovel Valves Pvt. Ltd. stands at the forefront of this evolution, combining decades of expertise with innovative engineering. Specializing in Dual Plate Check Valves, Non-Slam Nozzle Check Valves, Single Disc Check Valves, Piston Lift Check Valves, and Swing Type Check Valves, Flovel’s products are trusted by leading organizations worldwide, including ADNOC, Qatar Energy, and Shell.

With certifications such as API6D, API594, ISO 9001:2015, and CE-PED, Flovel Valves exemplify the best of modern valve technology, delivering reliability and performance across diverse industries.

Conclusion: The Future of Check Valves

From their humble beginnings in ancient Rome to the sophisticated designs of today, check valves have come a long way. As industries continue to evolve, so will the technology behind these critical components. With advancements in materials, automation, and sustainability, the future promises even greater innovations, ensuring that check valves remain indispensable in the world of engineering.

Whether you’re maintaining a legacy pipeline or planning a state-of-the-art industrial facility, understanding the evolution of check valves underscores their enduring importance in ensuring safe and efficient operations.